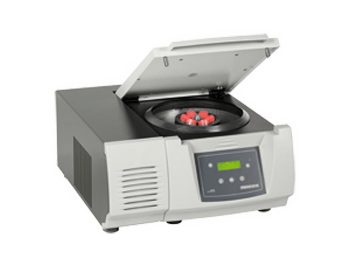

Max. capacity: 8 x 100 ml. (8/6”)

Max. speed: 2.425 xg / 3.000 RPM

The largest of our centrifuges for oil, with capacity for 8 tubes of 8”, the best option for centres that carry out a large number of tests every day.

If you need discussion about this product, please click “Find Solution”. Or click the “Order Now” to buy now.

Features Centrifuge Digtor 22 C-8

Designed for oil/petrol applications according the standards: ASTM D 91, D96, D 893, D 1796, D2273, D2709, D 2711, D 4007, D 5546, API 2542, API 2548, BS 4385, ISO 3734, ISO 9030, IP75, IP 359, NF M07-020, DIN 51793.

Tubes upright on rest.

Gas Release System (GRS): Gas release system (optional); pre-installation included.

TFT color touch screen, visible from more than 3 m.:

- Shows RPM and RCF, time, temperature, acceleration/deceleration values (PCBS and unbalancing location system (ULS).

- Speed programming in 10 RPM/10 xg steps.

- Real RCF values on screen based in accessories configuration.

- Count up/down from “0” or at “set RPM/RCF” for test reproducibility.

- Timer countdown/up from “0” or at “set RPM/ RCF” for reproducible tests.

- Timer from 1 min to 99 hours programmable in 1 sec. steps and hold position.

- PCBS: Progressive controlled acceleration and braking system up to 175 selectable ramps that prevents sample homogenization after separation.

- ULS: Unbalancing location system indicating on the screen the number of the bucket which produces the unbalance switch off.

- 40 programmable memories, with protection under password.

- Several acoustic and visual messages warning the user the device situation.

User friendliness

- Microprocessor controlled. PC connection.

- Induction motor maintenance free (brushless).

- Rotors and adapters list on memory.

- Noise level: below 60 dB.

- Start, stop, open lid and short spin with adjustable speed buttons.

- Option of free/locked adjustment of RPM/ RCF along the run.

- Last values remain in memory.

- Automatic rotor recognition. Over-speed protection.

Safety

- Lid provided with security systems:

– Automatic lid lock system, motorized with double lock.

– Emergency lid-lock release.

– Locking and protection against opening along the run.

– Lid dropping protection.

– Port in the lid for calibration and operation checking. - Unbalance detection and switch off.

- Protection safety ring between the centrifugation chamber and the housing.

- Chamber of centrifugation in stainless steel (easy cleaning).

- Rotors and adapters autoclavable, easy to install by the user.

- Automatic disconnection for energy saving up to 8 h.

Heating

- Preheating program with rotor spinning and temperature selectable. Allows keep the chamber at working temperature before starting the process.

- Regulation of the room temperature +5°C (41°F) to 80°C (176°F) in 1°C/1° F steps Programmable in °C o °F.

- Temperature sensor inside the chamber. Overheating protection.

- Internal isolated avoiding heat lost.

Standards and Directives

EU Directives: 2011/65/EU, 2012/19/EU, 2014/30/EU, 2014/35/EU, 98/79/EC.

Standards: EN 61010-1, EN 61010-2-020, EN 61326-2-6, EN 61326-1, EN 61010-2-010.

| Version | CE 198 | CE 199 |

| Dimensions (mm)(w x d x h) | 540 – 650 – 400 | 540 – 650 – 400 |

| Net weight (Kg) | 77 | 77 |

| Voltage (V) | 220-230 | 110-120 |

| Frecuency (Hz) | 50-60 | 50-60 |

| Consumption (W) | 1260 | 1220 |

The analytic sieve shaker OASS203 is designed to obtain reproducible results in accordance with the standard ISO 9001 for measuring and control equipment.