Hardness Tester adalah sebuah alat atau instrumen laboratorium dalam bidang farmasi yang berfungsi untuk menguji kekerasan sediaan tablet. Selain itu, hardness tester termasuk ke dalam alat yang berhubungan dengan kualitas sediaan tablet. Pada artikel kali ini, penulis akan membahas beberapa point penting seperti Pengertian Hardness Tester, Fungsi Hardness Tester, Prinsip Kerja Hardness Tester, Bagian Hardness Tester, Cara Menggunakan Hardness Tester, Cara Merawat Hardness Tester, Brand Hardness Tester, Spesifikasi Hardness Tester, Harga Hardness Tester dan Tempat Jual Hardness Tester.

PT. Andaru Persada Mandiri sebagai distributor alat laboratorium menjual Hardness Tester dengan berbagai jenis. Untuk informasi lebih lengkap, anda bisa menghubungi customer service kami via whatsapp 087777277740, telepon (0251) 7504679 atau berkunjung ke kantor langsung. Link produk Hardness Tester kami sertakan disini: Hardness Tester

Baca juga : Daftar Alat Laboratorium Beserta Fungsinya

Apakah beberapa dari anda sudah tahu dan sudah sering menggunakan alat hardness tester ? Atau ada juga yang belum pernah menggunakan hardness tester ?? Untuk itu, kita bisa pelajari melalui artikel ini. Silahkan di simak ya..

Pengertian Hardness Tester

Apa itu hardness tester ?? Nama hardness tester ini berasal dari dua kata yaitu “hard” yang berarti keras dan “tester” yang berarti percobaan atau pengujian. Jadi, hardness tester adalah suatu alat yang digunakan untuk menguji kekerasan sediaan. Tentu saja, sediaan yang digunakan adalah tablet. Berikut ini adalah gambar alat hardness tester :

Kenapa harus tablet ? Karena sediaan tablet dibuat dari beberapa bahan salah satunya adalah bahan pengikat yang membuat sediaan menjadi padat dan keras. Sehingga memungkinkan untuk di uji kekerasannya. Oh iya, hardness tester ini merupakan salah satu alat yang berperan dalam menentukan kualitas dan sifat fisik obat.

Apa itu Uji kekerasan ?

Uji kekerasan adalah upaya yang dilakukan untuk mengetahui seberapa kuat tablet itu bertahan terdapa tekanan yang diberikan. Tujuan utama dari uji kekerasan ini yaitu untuk menentukan kesesuaian suatu bahan dengan memberikan perlakuan khusus terhadap bahan tersebut. Nilai kuantitatif kekerasan harus selalu di evaluasi dalam beberapa faktor, diantaranya :

- pilihan metode tes

- gaya uji yang diterapkan pada indentor

- lamanya waktu indentor tetap berada dalam material

- geometri indentor

- geometri benda kerja

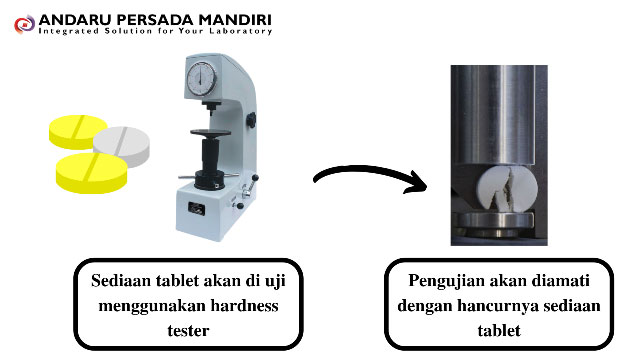

Dibawah ini adalah contoh gambar sediaan tablet ketika di uji menggunakan hardness tester :

Faktor faktor yang mempengaruhi uji kekerasan tablet

Ternyata, ada beberapa faktor yang dapat mempengaruhi hasil pengujian kekerasan. Sebagai aturan umum, semakin rendah beban yang anda gunakan dalam uji kekerasan, semakin banyak faktor yang perlu dikontrol untuk memastikan keakuratan dari uji kekerasan.

Berikut ini beberapa faktor penting yang harus dipertimbangkan pada uji kekerasan tablet, yaitu :

- Faktor eksternal seperti cahaya, kotoran, getaran, suhu, dan kelembapan harus dikontrol

- Alat hardness tester harus diletakkan di atas meja yang kokoh, dan sampel harus dijepit atau dipegang di penahan atau landasan.

- Indentor harus tegak lurus dengan permukaan yang diuji

- Pengaturan iluminasi harus konstan selama pengujian saat menggunakan vickers, knoop dan brinell

- Hardness tester harus dikalibrasi ulang setiap kali anda mengganti indentor

Fungsi Hardness Tester

Seperti yang sudah dibahas pada point diatas, hardness tester berfungsi sebagai alat yang digunakan untuk menguji kekerasan pada sediaan tablet. Penggunaan hardness tester ini menjadi hal yang penting dalam bidang farmasi. Nah, hardness tester sering digunakan bersamaan dengan alat pengujian tablet lainnya seperti friability tester, dissolution tester dan disintegration tester. Sebenarnya, kekerasan tablet ini bukan bentuk spesifik dari sediaan, tetapi lebih di definisikan sebagai ketahanan dari material yang digunakan terhadap perubahan bentuk dengan material lain yang lebih keras.

Penggunaan Hardness Tester di Laboratorium Farmasi

Biasanya, penggunaan hardness tester di laboratorium farmasi ini lebih fokus untuk mendapatkan hasil penelitian dan pembelajaran. Apalagi di sarana kampus. Sebelum pengujian, mahasiswa akan membuat sediaan tablet terlebih dahulu dengan formulasi yang pas dan sesuai. Setelah sediaan sudah jadi, baru lah dilakukan berbagai pengujian tablet salah satunya uji kekerasan menggunakan hardness tester. Alat hardness tester akan mempermudah untuk mengetahui ketahanan dan kekuatan tablet. Hal ini juga bisa menjadi perbandingan dari jumlah bahan pengikat yang digunakan.

Penggunaan Hardness Tester di Industri

Tentu saja, hardness tester ini sangat penting dalam industri terutama industri farmasi. Uji kekerasan melibatkan penentuan nilai karakteristik (nilai kekerasan) yang sangat penting untuk menilai penggunaan bahan dalam industri atau kesesuaian bahan untuk bagian yang relevan secara teknis, penerimaannya selama inspeksi sebagai bagian dari jaminan kualitas (barang masuk dan keluar pemeriksaan barang), untuk membedakan antara bahan (misalnya dalam jumlah material) dan untuk menganalisis kerusakan. Oh iya, di bidang industri pengujian kekerasan tablet menggunakan hardness tester termasuk dalam sistem quality control ya.

Sediaan tablet memang harus mudah larut ketika sudah dikonsumsi, tapi bukan berarti harus lunak juga ya. Jika sediaan tablet mudah hancur, itu akan membuat kualitas sediaan menurun dan tidak layak untuk dikonsumsi.

Alat Hardness Tester dalam Penelitian Sifat Fisik Obat

Penulis telah menemukan salah satu jurnal dari Polteknik Kesehatan Kemenkes Manado yang berjudul “Uji Kekerasan, Keregasan dan Waktu Hancur Beberapa Tablet Ranitidin”. Dalam jurnal tersebut telah dijelaskan beberapa pembahasan yang berhubungan dengan uji kekerasan tablet. Bahwa sediaan tablet harus memiliki kekuatan dan ketahanan untuk menghindari kerusakan pada saat terjadi tekanan, guncangan, pembuatan, dan pengemasan barang.

Setelah diperoleh hasilnya, ada beberapa faktor yang mempengaruhi kekerasan tablet seperti tekanan kompresi dan sifat bahan yang digunakan. Menurut Farmakope Indonesia, sediaan tablet dapat dikatakan baik jika memiliki tingkat kekerasan antara 4 – 8 kg. Nah, hasil jurnal tersebut menunjukkan bahwa tablet ranitidin memiliki tingkat kekerasan lebih dari 11 kg. Maka, dapat disimpulkan bahwa tablet ranitidin tersebut tidak memenuhi syarat dalam uji kekerasan.

Prinsip kerja hardness tester

Bagaimana proses kerja dari hardness tester sehingga dapat mengetahui tingkat kekerasan tablet ? Dalam proses kerjanya, hardness tester akan memaksa bagian indentor yang merupakan komponen utama untuk menekan ke permukaan tablet diikutin dengan pengukuran kedalaman atau luas permukaan tablet yang sebenarnya.

Tekanan yang diberikan akan membuat keretakan atau pecahnya sediaan tablet. Dari sini lah anda bisa mendapatkan hasilnya dan memastikan seberapa besar kekuatan dan ketahanan yang dimiliki oleh tablet tersebut. Kerusakan tablet dapat menjadi evaluasi anda untuk melakukan reformulasi dengan menambahkan jumlah bahan pengikat lebih banyak dari sebelumnya.

Metode Pengujian Kekerasan Tablet

Sobat sudah tahu belum? Alat hardness tester ini bekerja dengan beberapa metode seperti Rockwell hardness, Vickers hardness, Knoop hardness dan Brinell hardness. Bagaimana proses kerja dari masing masing metode tersebut ? Berikut Penjelasannya

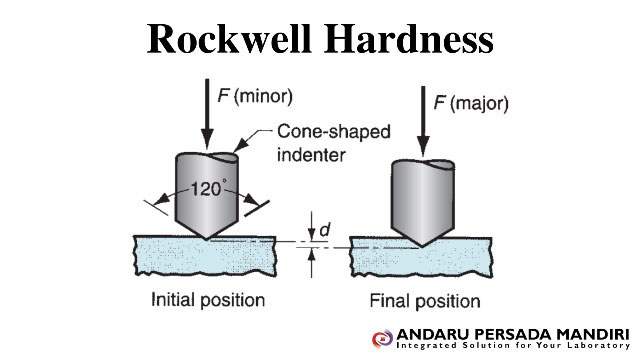

Rockwell hardness

Yang pertama ada Rockwell hardnes. Metode rockwell adalah salah satu metode pengujian kekerasan statis dalam rentang makro, lebih tepatnya memiliki gaya uji sekitar 29,42 hingga 1471 N. Rockwell hardness sering disebut sebagai “metode kedalaman diferensial” yang artinya kedalaman sisa lekukan yang ditinggalkan oleh indentor untuk mengetahui nilai kekerasan suatu benda uji.

Bentuk dan bahan indentor pada metode ini tergantung pada Rockwell tertentu yang digunakan, indentor dapat berupa kerucut berlian (dengan sudut kerucut 120°) atau bola logam keras (dengan berbagai diameter tergantung pada metodenya).

Dalam uji kekerasan Rockwell, metode kedalaman diferensial, kedalaman sisa indentasi yang dibuat oleh indentor diukur. Semakin dalam indentor yang ditentukan menembus pada gaya uji yang ditentukan ke permukaan benda kerja (spesimen), semakin lembut bahan yang diuji. Adapun beberapa nilai kekerasan pada metode rockwell, diantaranya :

- Nilai kekerasan numerik

- Dua huruf “HR”, singkatan dari “Hardness menurut Rockwell”

- Penunjukan skala rockwell, mendefinisikan kombinasi beban utama (gaya uji total) dan jenis indentor yang digunakan dalam metode Rockwell yang sesuai.

Kelebihan Rockwel Hardness :

- Tidak memerlukan proses pemisahan dan pencampuran.

- Nilai kekerasan dapat langsung dibaca, tidak memerlukan evaluasi optik.

- Prosesnya cepat dan hemat biaya

- Pengujiannya bersifat non-destruktif (benda uji dapat digunakan untuk tujuan lain).

Kekurangan Rockwell Hardness :

- Kurang akurat, karena jika pengukurannya tidak teliti maka dapat menyebabkan kesalahan yang signifikan dalam nilai kekerasan yang dihitung.

- Tempat pengujian harus benar-benar bebas dari kontaminasi (misalnya kerak, benda asing atau minyak) . untuk mencapai hasil pengujian yang sesuai.

- Indentor memiliki efek yang tidak diketahui pada hasil pengujian. misalnya. jika indentor sudah longgar dan ujungnya tidak lagi cukup lancip.

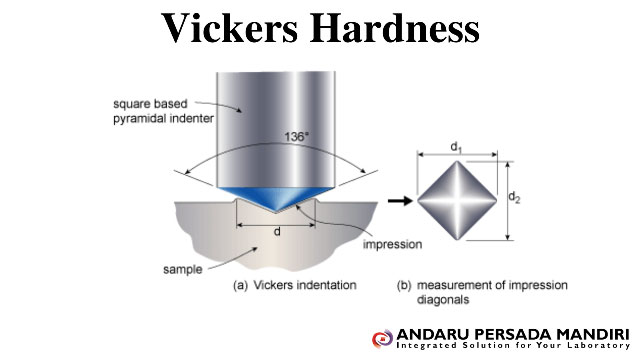

Vickers Hardness

Selanjutnya ada vickers hardness adalah suatu metode uji kekerasan yang dapat digunakan pada semua rentang beban. Menurut ISO, vickers hardness ini memiliki rentang beban uji dari 1 kgf hingga 12 kgf. Metode vickers ini dikenal dengan “metode optik”yang artinya ukuran lekukan yang ditinggalkan oleh indentor diukur untuk mengetahui nilai kekerasan suatu benda uji. Indentor pada metode vickers berbentuk piramida sama sisi (dengan alas persegi) yang terbuat dari berlian dengan sudut bidang 136°.

Dalam uji kekerasan vickers, ukuran lekukan (diagonal) yang ditinggalkan oleh indentor diukur. Sebaliknya, kedalaman lekukan yang disebabkan oleh indentor diukur dalam metode pengukuran kedalaman (rockwell). Semakin besar lekukan yang ditinggalkan oleh indentor pada gaya uji yang ditentukan di permukaan benda kerja (spesimen), semakin lembut bahan yang diuji. Adapun nilai kekerasan Vickers terdiri dari komponen-komponen berikut:

- Nilai kekerasan numerik (antara 1 dan 3000)

- Dua huruf “HV”, singkatan dari “kekerasan menurut vickers”

- Beban uji yang diterapkan dalam kgf

- Waktu diam dari beban uji

Dibawah ini adalah ilustrasi proses kerja dari metode vickers hardness :

Kelebihan Vickers Hardness :

- Dapat digunakan dengan semua bahan dan benda uji, dari lunak hingga keras, karena prosedur ini mencakup seluruh rentang kekerasan.

- Hanya ada satu jenis indentor, yang dapat digunakan untuk semua metode Vickers.

- Pengujiannya bersifat non-destruktif , sehingga benda uji dapat digunakan untuk tujuan lain.

Kekurangan Vickers Hardness :

- Kualitas permukaan benda uji harus baik, karena lekukan diukur secara optik.

- Prosesnya lambat. Siklus pengujian berlangsung antara 30 dan 60 detik, tidak termasuk waktu yang dibutuhkan untuk menyiapkan sediaan.

- Karena kebutuhan untuk melakukan evaluasi indentasi optik, penguji kekerasan vickers harus dilengkapi dengan sistem optik, sehingga biayanya sangat mahal.

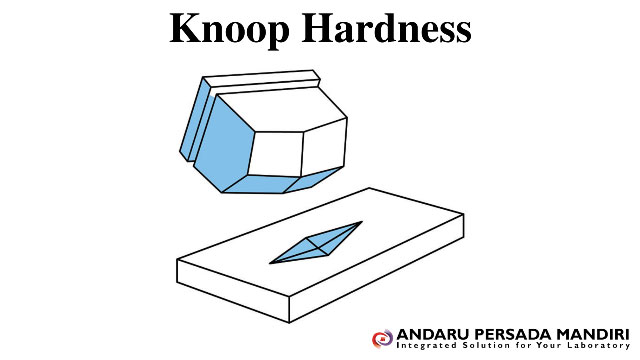

Knoop Hardness

Metode knoop hardness adalah pengujian yang dilakukan dikembangkan sebagai alternatif metode vickers serta digunakan khususnya untuk pengujian lapisan tipis dan bahan getas. Menurut ISO, metode ini memiliki rentang beban uji 1 kgf hingga 2 kgf , yang berarti metode ini dapat digunakan untuk pengujian kekerasan pada rentang beban mikro dan rendah. Bagian indentore pada knoop hardness berbentuk piramida dengan alas belah ketupat, dengan sudut tepi memanjang 172,5° dan sudut tepi melintang 130°. Berikut ini adalah ilustrasi dari metode knoop hardness :

Nilai yang dihasilkan oleh metode knoop berasal dari beberapa komponen, diantaranya :

- Nilai kekerasan numerik

- Dua huruf “HK”, singkatan dari “kekerasan menurut knoop”

- Beban uji yang diterapkan dalam kgf

- Waktu diam dari beban uji

Kelebihan metode knoop hardness :

- Metode knoop dapat digunakan dengan semua bahan dan benda uji

- Hanya ada satu jenis indentor yang dapat digunakan untuk semua metode knoop.

- Pengujiannya lebih tepat daripada metode vickers, karena diagonal pengukuran knoop lebih panjang untuk setiap kedalaman lekukan tertentu.

- Metode ini tidak merusak keseluruhan dibandingkan dengan metode vickers, karena kedalaman lekukan dan risiko pembentukan retak pada tepi lekukan pada kaca dan keramik lebih rendah.

- Sangat cocok untuk menguji komponen kecil, agak panjang dan lapisan yang sangat tipis serta bahan rapuh yang tidak sesuai dengan metode lain.

Kekurangan metode knoop hardness :

- Kualitas permukaan benda uji harus baik, karena lekukan diukur secara optik. Ini berarti bahwa lokasi pengujian harus disiapkan.

- Prosesnya agak lambat. Waktu pengujian berlangsung antara 30 dan 60 detik, tidak termasuk waktu yang dibutuhkan untuk menyiapkan benda uji.

- Karena kebutuhan untuk melakukan evaluasi indentasi optik, maka biaya nya lebih mahal.

Brinell Hardness

Yang terakhir ada brinell yaitu metode pengujian kekerasan adalah metode pengujian kekerasan yang memiliki rentang beban uji 1 hingga 3000 kgf. Itu berarti metode ini dapat digunakan untuk pengujian kekerasan pada beban rendah dan rentang makro (rentang konvensional). Bentuk indentornya seperti bola logam tungsten karbida, dengan diameter 1, 2,5, 5 atau 10 mm. Dalam uji kekerasan brinell, ukuran lekukan yang ditinggalkan oleh indentor diukur. Berikut ini beberapa nilai brinell hardness dari komponen yang ada seperti :

- Nilai kekerasan numerik

- Tiga huruf “HBW”, singkatan dari “kardness menurut brinell”

- Diameter bola dalam satuan mm

- Beban uji yang diterapkan dalam kgf

- Waktu diam dari beban uji

Dibawah ini adalah contoh ilustrasi dari metode brinell :

Kelebihan Brinell hardness :

- Metode yang dapat digunakan untuk menguji bahan non-homogen.

- Dapat dibuat antara sejumlah besar gaya uji dan diameter bola untuk berbagai aplikasi

- Pengujiannya mudah dilakukan.

Kekurangan brinell hardness :

- Permukaan benda uji harus dalam keadaan baik, karena lekukan diukur secara optik.

- Resiko kesalahannya lebih besar.

- Prosesnya lambat. Pengujiannya dilakukan antara 30 dan 60 detik.

Saat ingin memilih salah satu metode diatas, sebaiknya perhatikan dulu beberapa hal penting seperti :

- Jenis bahan yang akan diuji kekerasannya Apakah kepatuhan terhadap standar diperlukan Perkiraan kekerasan material Homogenitas/heterogenitas bahan Ukuran bagian Apakah pemasangan diperlukan Jumlah sampel yang akan diuji Keakuratan hasil yang dibutuhkan

Sudah banyak sekali point yang sudah dibahas.. Sekarang kita lanjut lagi yuk..

Jenis Jenis Hardness Tester

Ternyata, hardness tester ini terdiri dari enam jenis lho… Ada bench top hardnes tester, stracth hardness tester, dynamic hardness tester, manual hardness tester, portable hardness tester, dan digital hardness tester. Penjelasannya ada dibawah ini yaa.

Benchtop Hardness Tester

Yang pertama ada benchtop hardness tester yang merupakan jenis paling umum. Hampir di setiap laboratorium farmasi memiliki benchtop ini. Sampel atau sediaan obat akan diletakkan di alas, kemudian anda bisa mengatur posisi indentor nya sampai sesuai dengan letak sampel.

Scratch Hardness Tester

Selanjutnya scratch hardness tester adalah salah satu jenis alat uji kekerasan yang hampir jarang dimiliki oleh laboratorium farmasi guys. Padahal scratch hardness ini mampu menahan goresan pada permukaan sampel, sehingga sampelnya tidak rusak.

Dynamic Hardness Tester

Alat dynamic hardness tester. Bentuknya sangat simple dan bekerja dengan bantuan energi. Sediaan akan dijatuhkan, kemudian dynamic hardness tester akan menghitungan jumlah pantulannya. Pantulan tersebut merupakan salah satu hal dalam mengamati ketahanan tablet.

Manual Hardness Tester

Bisa dibilang, jenis manual ini termasuk hardness tester yang masih “kuno”. Pengunaannya harus membutuhkan tenaga untuk menekan tuas hingga menjepit sediaan yang diuji. Untuk melihat hasil kekerasannya, anda bisa mengamati skala yang ada di bagian alat tersebut.

Portable Hardness Tester

Jenis portable ini bentuknya seperti remote yang mudah dibawa kemana saja. Tentunya, alat ini sangat ringan. Pengunaannya pun sangat mudah. Untuk membaca hasilnya, anda bisa melihat langsung pada LCD display nya.

Digital Hardness Tester

Kalau sudah ada kata “digital”, bisa dipastikan alat ini lebih canggih dari jenis lainnya. Yup, digital hardness tester adalah salah satu jenis alat uji kekerasan tablet yang sudah canggih. Karena, anda hanya memasukkan tablet ke dalam ruangan kecil pada alat, setelah itu alat akan berjalan secara otomatis. Ketika sudah berhenti, anda bisa melihat hasilnya pada control panel. Selain itu, digital hardness tester ini memiliki beberapa tombol dan keyboard.

Bagian Bagian Hardness Tester

Kalau anda amati, alat hardness tester ini memiliki beberapa bagian penting yang dapat membantu proses kerjanya. Berikut ini bagian dari salah satu jenis hardness tester yaitu bench top hardness tester, diantaranya :

Dial

Bagian dial berada di depan alat yang menunjukkan besarnya beban dari sediaan obat dengan satuan kgf. Dial berbentuk menyerupai kompas yang berisi beberapa angka serta jarum untuk menunjukkan hasil bebannya.

Indentor

Selanjutnya ada indentor. Bagian indentor ini terbuat dari baja yang kuat sehingga mampu meberi tekanan pada sediaan obat. Selain itu, indentor memiliki bentuk sudut tumpul yang akan menekan permukaan sampel.

Working Table

Bagian working tbale merupakan landasan dengan permukaan yang rata untuk meletakkan sediaan obat. wroking table berada di bagian bawah indentor.

Handwheel

Handwheel adalah salah satu bagian hardness tester yang berfungsi untuk mengatur atau menyesuaikan ketinggian dari working table.

Crank Handle

Nah, crank handel ini berada di bagian samping bawah alat yang mampu menurunkan beban mayor pada hardness tester.

Elevating screw

Elevating screw atau bisa disebut dengan “tiang penyangga” yang berfungsi untuk menahan work table. Selain itu, elevating screw merupakan perantara dalam menyesuaikan tinggi dari work table dengan cara naik turun menggunakan handwheel.

Baca juga : Konsultan Alat Laboratorium

Cara Menggunakan Hardness Tester

Berikut ini adalah cara menggunakan hardness tester jenis bench top dengan baik dan benar :

- Siapkan sediaan obat yang akan di uji.

- Letakkan tablet diatas work table, sejajar dengan posisi indentor.

- Putar handwhell untuk mengatur ketinggian work table hingga mendekati indentor.

- Kemudian, putar crank handle hingga indentor menekan sediaan tablet.

- Setelah itu, jika terjadi keretakan pada tablet hasilnya akan terlihat di bagian dial.

- Putar kembali handwheel untuk menurunkan work table.

- Ambil sediaan obat yang sudah di uji.

- Bersihkan work table dari sisa sisa bahan yang menempel.

Cara Merawat Hardness Tester

Ketika ingin melalukan uji kekerasan di laboratorium, anda bisa langsung menggunakan alat nya. Padahal, tanpa diketahui, beberapa pekerja di laboratorium atau laboran telah memberikan perawatan khusus pada alat hardness tester tersebut.

Perawatan rutin yang dilakukan akan mengurangi kerusakan pada alat. Jenis perawatan yang paling umum dilakukan adalah dengan membersihkan work table atau permukaan landasan menggunakan tissue. Selain itu, ada juga beberapa perawatan khusus yang dilakukan, seperti :

- Mengencangkan handwheel dan crank handle, agar bisa mengatur ketinggian work table dengan baik.

- Membersihkan bagian indentor menggunakan kuas. Jika ada masalah serius, bisa dibongkar menggunakan alat mekanik. Tapi, hal ini harus dilakukan oleh tenaga ahli ya.

- Rutin mengganti oli, agar indentor dapat bergerak dengan lancar. Untuk mengganti oli, Anda harus melepas mur kantung dan kantung karet, mengeluarkan semua oli lama dari mesin, dan mengisi oli kembali hingga lubang bah tertutup. Setelah lubang bah ditutup, Anda harus memasang kembali mur kantung dan kantung karet, memperbaiki ram, dan mengkalibrasi mesin lagi.

- Kalibrasi. Proses kalibrasi ini sangat penting dilakukan untuk mengontrol keakuratan dari alat tersebut.

Kalibrasi Hardness Tester

Instrumen hardness tester harus dikalibrasi secara berkala untuk memastikan bahwa alat tersebut masih berfungsi dengan baik dan akurat. Karena proses pengujiannya dilakukan berulang kali hingga terjadi tekanan dan goresan, maka bisa membuat posisi indentor tidak sejajar. Kalibrasi juga bertujuan untuk mengembalikan kehandalan alat .

Kalibrasi harus dilakukan secara berkala untuk memverifikasi bahwa akurasi instrumen berada dalam toleransi yang dinyatakan pabrikan untuk grade atau model. Karena penguji kekerasan berulang kali mengukur ketahanan relatif bahan terhadap penyok, tekukan, atau goresan, itu bisa menjadi tidak sejajar. Kalibrasi dan penyesuaian akan diperlukan untuk mengembalikan keandalannya. Pada umunya, kalibrasi hardness tester dilakukan tiap 6 bulan sekali.

Dibawah ini adalah cara kalibrasi alat hardness tester :

- Sebelum kalibrasi alat uji kekerasan, mesin diratakan dan diperiksa apakah ada yang patah atau retak.

- Proses kalibrasi melibatkan kondisi landasan dan indentor, kemudian menjalankan lima uji kekerasan pada rentang tinggi, menengah dan rendah pada semua skala yang disesuaikan.

- Jika instrumen membaca dalam toleransi blok uji, mesin dianggap dapat disertifikasi.

- Jika tidak, penyesuaian akan dilakukan untuk memperbaiki mesin. Metode verifikasi ini memperhitungkan dan menggabungkan semua variabel yang menghasilkan angka kekerasan aktual, seperti yang akan dilakukan selama pengujian aktual.

Brand Hardness Tester

Suatu alat hardness tester ini telah dikembangkan oleh beberapa brand atau merk. Salah satu brand hardness tester yang banyak direkomendasikan adalah “Copley”. Brand Copley telah mengembangkan alat hardness tester dengan tipe yang bervariasi. Selain itu, ada juga nih beberapa brand yang ikut mengembangkan alat hardness tester, antara lain :

- Novotest

- ErwekA

- Labtron

- Senieer

Spesifikasi Hardness Tester

Dibawah ini adalah spesifikasi singkat alat hardness tester dari brand Copley :

|

Harga Hardness Tester

Berbicara soal harga, hardness tester ini termasuk alat laboratorium yang dijual dengan cukup mahal guys. Distributor yang menjual hardness tester ini menawarkan dengan harga yang bervariasi tergantung dari jenis, spesifikasi dan brand nya. PT. Andaru Persada Mandiri adalah salah satu distributor alat laboratorium yang menjual hardness tester dari brand Copley dengan harga RP. 218.000.000 saja. Hrga tersebut sudah termasuk training penggunaan, kalibrasi, sevrice rutin serta perbaikan jika terjadi kerusakan.

Beberapa distributor lainnya juga menjual hardness tester. Berikut penulis buatkan daftar harga hardness tester yang sudah di ambil dari beberapa marketplace.

|

Jenis Hardness Tester |

Harga Hardness Tester |

| Bench top hardness tester | Rp. 70.000.000 – Rp. 150.000.000 |

| Stracth hardness tester | Rp. 3.000.000 – Rp. 10.000.000 |

| Dynamic hardness tester | Rp. 30.000.000 – Rp. 50.000.000 |

| Manual hardness tester | Rp. 1.000.000 – Rp. 3.000.000 |

| Portable hardness tester | Rp. 10.000.000 – Rp. 40.000.000 |

| Digital hardness tester | Rp. 150.000.000 – Rp. 350.000.000 |

Tempat Jual Hardness Tester

Anda bisa mendapatkan atau membeli hardness tester di distributor alat laboratorium resmi salah satunya PT. Andaru Persada Mandiri. Selain itu, anda juga bisa mencari nya secara online di beberapa aplikasi marketplace seperti shopee, tokopedia, bukalapak, dan masih banyak lagi.

FAQ Tentang Alat Hardness Tester

Dibawah ini kumpulan pertanyaan beserta jawaban seputar alat hardness tester yang dirangkum dari pembahasan diatas.

Apa itu hardness tester ?

Hardness Tester adalah sebuah alat atau instrumen laboratorium dalam bidang farmasi yang berfungsi untuk menguji kekerasan sediaan tablet.

Mengapa uji kekerasan menggunakan sediaan tablet ?

Karena sediaan tablet dibuat dari beberapa bahan salah satunya adalah bahan pengikat yang membuat sediaan menjadi padat dan keras.

Apa fungsi dari hardness tester ?

hardness tester berfungsi sebagai alat yang digunakan untuk menguji kekerasan pada sediaan tablet.

Faktor apa saja yang menjadi pertimbangan dalam uji kekerasan tablet?

- Faktor eksternal seperti cahaya, kotoran, getaran, suhu, dan kelembapan harus dikontrol

- Alat hardness tester harus diletakkan di atas meja yang kokoh, dan sampel harus dijepit atau dipegang di penahan atau landasan.

- Indentor harus tegak lurus dengan permukaan yang diuji

- Pengaturan iluminasi harus konstan selama pengujian saat menggunakan vickers, knoop dan brinell

- Hardness tester harus dikalibrasi ulang setiap kali anda mengganti indentor

Bagaimana prinsip kerja dari hardness tester ?

Dalam proses kerjanya, hardness tester akan memaksa bagian indentor yang merupakan komponen utama untuk menekan ke permukaan tablet diikutin dengan pengukuran kedalaman atau luas permukaan tablet yang sebenarnya.

Tekanan yang diberikan akan membuat keretakan atau pecahnya sediaan tablet. Dari sini lah anda bisa mendapatkan hasilnya dan memastikan seberapa besar kekuatan dan ketahanan yang dimiliki oleh tablet tersebut. Kerusakan tablet dapat menjadi evaluasi anda untuk melakukan reformulasi dengan menambahkan jumlah bahan pengikat lebih banyak dari sebelumnya.

Apa saja yang termasuk bagian pada alat hardness tester ?

- dial

- indentor

- elevating screw

- crank handle

- handwheel

Kelebihan apa saja yang dimiliki metode rockwell ?

- Tidak memerlukan proses pemisahan dan pencampuran.

- Nilai kekerasan dapat langsung dibaca, tidak memerlukan evaluasi optik.

- Prosesnya cepat dan hemat biaya

- Pengujiannya bersifat non-destruktif (benda uji dapat digunakan untuk tujuan lain).

Bagaimana cara menggunakan hardness tester ?

- Siapkan sediaan obat yang akan di uji.

- Letakkan tablet diatas work table, sejajar dengan posisi indentor.

- Putar handwhell untuk mengatur ketinggian work table hingga mendekati indentor.

- Kemudian, putar crank handle hingga indentor menekan sediaan tablet.

- Setelah itu, jika terjadi keretakan pada tablet hasilnya akan terlihat di bagian dial.

- Putar kembali handwheel untuk menurunkan work table.

- Ambil sediaan obat yang sudah di uji.

- Bersihkan work table dari sisa sisa bahan yang menempel.

Perawatan apa saja yang dilakukan pada alat hardness tester ?

- Mengencangkan handwheel dan crank handle, agar bisa mengatur ketinggian work table dengan baik.

- Membersihkan bagian indentor menggunakan kuas. Jika ada masalah serius, bisa dibongkar menggunakan alat mekanik. Tapi, hal ini harus dilakukan oleh tenaga ahli ya.

- Rutin mengganti oli, agar indentor dapat bergerak dengan lancar. Untuk mengganti oli, Anda harus melepas mur kantung dan kantung karet, menuangkan semua oli lama dari mesin, dan mengisi oli kembali hingga lubang bah tertutup. Setelah lubang bah ditutup, Anda harus memasang kembali mur kantung dan kantung karet, memperbaiki ram, dan mengkalibrasi mesin lagi.

- Kalibrasi. Proses kalibrasi ini sangat penting dilakukan untuk mengontrol keakuratan dari alat tersebut.

Berapakah harga hardness tester ?

harga hardness tester tahun 2022 berkisar Rp. 1.000.000 hingga Rp. 350.000.000

Dimana kita bisa membeli hardness tester ?

Hardness tester bisa anda dapatkan di distributor alat laboratorium seperti PT. Andaru Persada Mandiri. Selain itu, anda juga bisa mencari nya secara online di beberapa aplikasi marketplace seperti shopee, tokopedia, bukalapak, dan masih banyak lagi.

Penulis : FR

Sebagai informasi tambahan, PT. Andaru Persada Mandiri adalah distributor alat laboratorium yang menyediakan solusi lengkap kebutuhan alat laboratorium. Bagi anda yang membutuhkan alat laboratorium bisa mengunjungi alamat googlemaps, menghubungi kami via whatsapp 087777277740 atau telepon 0251-7504679. Link brand dan produk alat laboratorium tersedia pada tautan : List Brand Alat Laboratorium

Demikian pembahasan tentang Hardness Tester, yang berisi Pengertian Hardness Tester, Fungsi Hardness Tester, Prinsip Kerja Hardness Tester, Bagian Hardness Tester, Cara Menggunakan Hardness Tester, Cara Merawat Hardness Tester, Brand Hardness Tester, Spesifikasi Hardness Tester, Harga Hardness Tester dan Tempat Jual Hardness Tester. Jika berkenan silahkan mengisi kolom komentar, sekian dan terima kasih.