Office

28865 Lilienthal (Germany)

Website

Focus Product

Industrial Furnaces.

Special Product

Furnace.

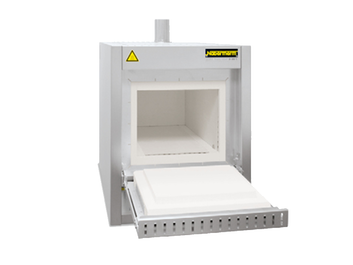

The muffle furnaces L 1/12 – LT 40/12 are the right choice for daily laboratory use. These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability. The muffle furnaces come equipped with either a flap door or lift door at no extra charge.

With their unbeatable price/performance ratio, these compact muffle furnaces are perfect for many applications in the laboratory. Quality features like the dual shell furnace housing of rust-free stainless steel, their compact, lightweight constructions, or the heating elements encased in quartz glass tubes make these models reliable partners for your application.

Heating elements on support tubes radiating freely into the furnace chamber provide for particularly short heating times for these muffle furnaces. Thanks to their robust lightweight refractory brick insulation, they can reach a maximum working temperature of 1300 °C. These muffle furnaces thus represent an interesting alternative to the familiar L(T) 3/11 models, when you need particularly short heating times or a higher application temperature.

These models stand out for their excellent workmanship, advanced and attractive design, and high level of reliability. Heating elements on support tubes radiating freely into the furnace chamber provide for particularly short heating times and a maximum temperature of 1400 °C. These muffle furnaces are a good alternative to the familiar L(T) ../11 series when higher application temperatures are needed.

We particularly recommend the muffle furnace L 9/11/SKM if your application involves aggressive substances. The furnace has a ceramic muffle with embedded heating from four sides. The muffle furnace thus combines a very good temperature uniformity with excellent protection of the heating elements from aggressive atmospheres. Another aspect is the smooth, nearly particle free muffle (furnace door made of fiber insulation), an important quality feature for some ashing processes.

The ashing furnaces LV 3/11 – LVT 15/11 are especially designed for ashing in the laboratory. A special air intake and exhaust system allows air exchange of more than 6 times per minute. Incoming air is preheated to ensure a good temperature uniformity.

The ashing furnace L ../11 BO is specially designed for processes in which larger sample quantities have to be incinerated. Fields of application are e.g. the ashing of food, thermal cleaning of injection molding tools or the determination of annealing loss. Another application is the debinding of ceramic products, e.g. after additive production.

This weighing furnace with integrated precision scale and software, was designed especially for combustion loss determination in the laboratory.